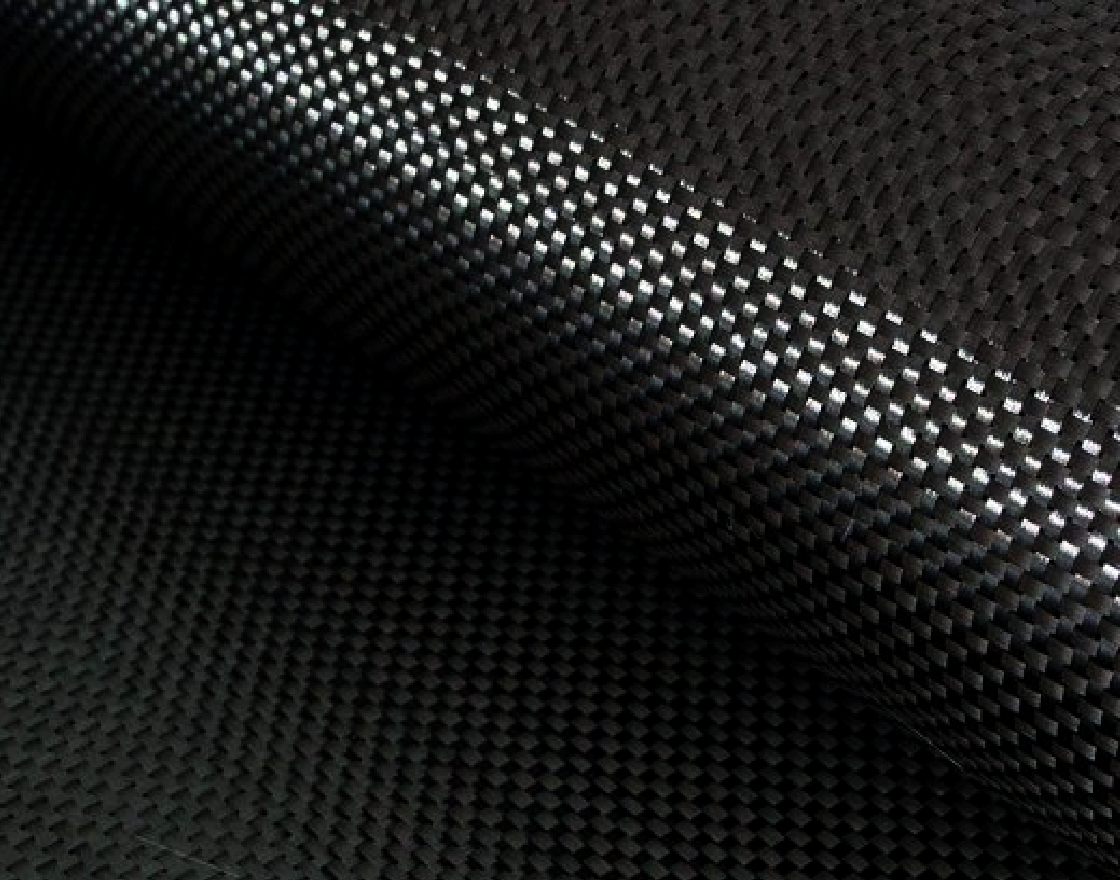

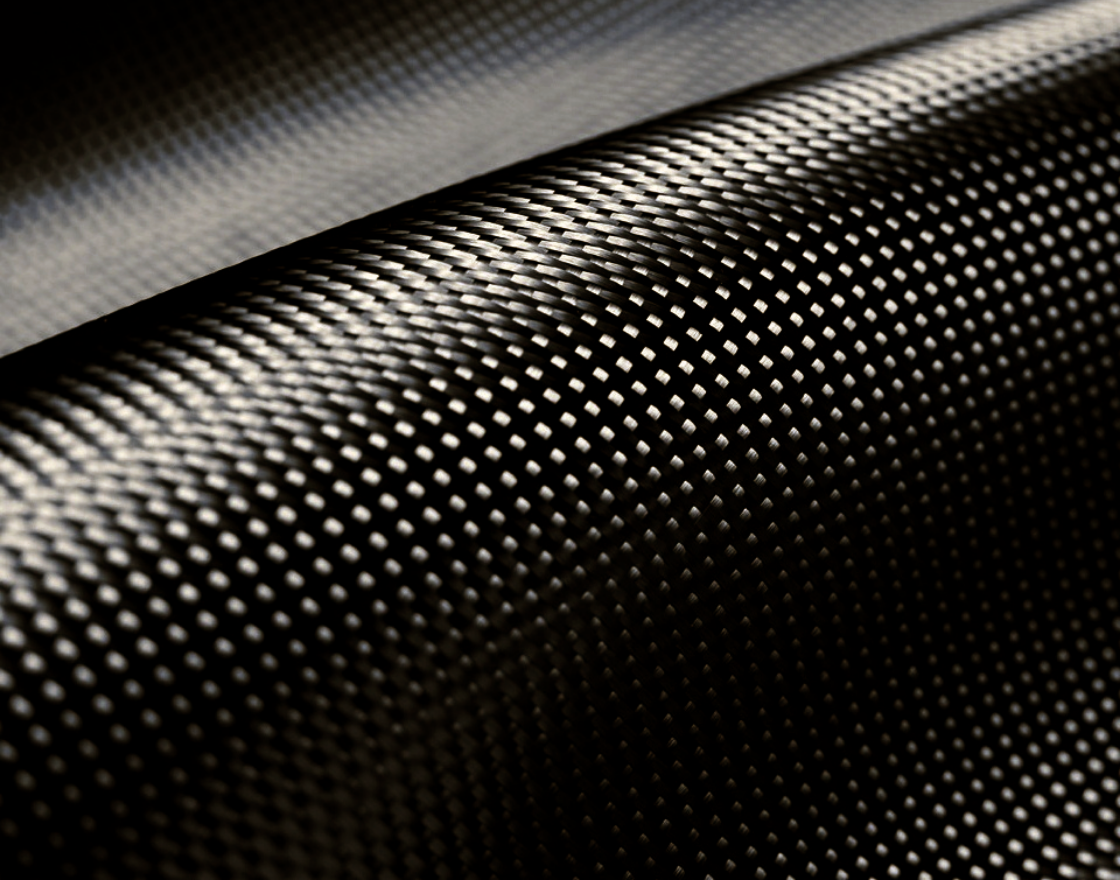

Carbon fiber roving is woven into fabric

Carbon fiber is composed of carbon atoms bonded together to form a long chain. The fibers are extremely stiff, strong, light. Carbon fiber strands are finer than a human hair. These strands are twisted together like yarn (called a tow) and woven into carbon fiber fabric.